請用 Wechat 掃描台灣精品QRcode 或 搜尋ID: TaiwanExcellence

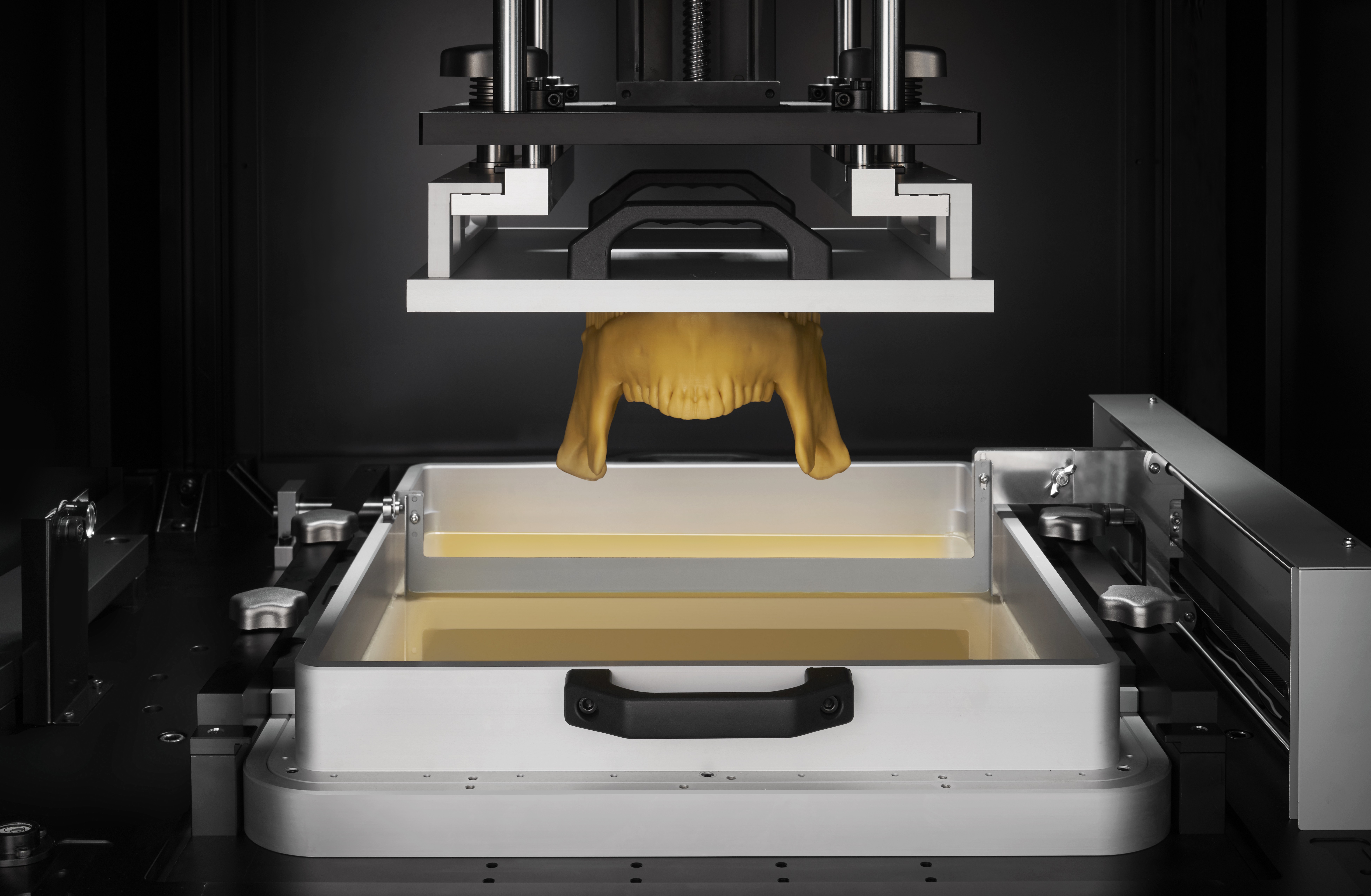

1. The largest printing area is 25cm in length and 23 cm in width, XY resolution is 125um, so the printing area is around 4 times greater compared to similar DLP printers on the market. 150 unit rings per print and 30 unit dental arches per print, improves production efficiency for traditional jewelry and the dental industry. This machine is also an economical choice for industrial and medical prototyping.

2. The printer XY resolution has four types: 30um, 65um, 100um and 125um. The Z axis mechanical structure makes layers stable, helping to provide a better printing success rate. The patented tilt structure reduces the risk of broken micro structure. Self developed image calibration software ”Utility” can do calibration, anti-aliasing, sharpness and resin compensation to make printing details perfect.

3. With 365nm to 405nm wavelength, most photopolymer resins can be used and the recoater function can help high viscosity resin forming.

About Young Optics Inc.

Young Optics, Inc. (“Young Optics”) was established in Hsinchu Science Park on 18th Feb.,2002 and acquired GTSM IPO filing successfully (ticker symbol #3504) in 26th Jan. ,2007 . We are engaged in research, design, manufacture and sales of optical components and modules with its manufacturing site in Hsinchu ,Taiwan ; KunShan, China; Suzhou, China, and Dhaka (Bangladesh).

With optical key knowledge, one-stop purchasing and manufacturing advantage, we aim to support Branding/System corp. to approach target markets and also creating win-win advantage for both.

We believe where there's human needs, where Young optics exists. Traditional jewelry production process is time-consuming and costly, but with light-cured 3D printer, it shortens the production time and enables customized jewelry. Wherefore in 2012, we developed the first high precision DLP 3D Printer in Taiwan and keep introducing new generation 3D printers since then.

MiiCraft’s earliest 3D printer prototype originated from the team’s persistence in coming up with an exceptional product. An unfinished optic projection project with Japan ignited the team’s determination and passion in developing a 3D printer for the market. The team underwent countless sketch drawings and continuously sought suitable materials before coming up with a second proposal for the company. After considerable effort, the team finally came up with their first 3D Printer prototype.

The patent of photopolymerization was expired in 2012, it let more and more providers joined in, and the whole world was depicting the prosperous era of makers. MiiCraft’s first 3D printer utilized innovated pico light engine inside, it was the smallest DLP 3D printers at that time, well suited for home-use and small studios.

The brand was named MiiCraft, meaning a forming tool of easy accessibility for everyone.

During an exhibition for new products, an Italian jewelry equipment manufacturer was amazed by the sophisticated printed parts generated from MiiCraft 3D printers. If castable photopolymer resins could be used, the wax model of rings could be replaced by 3D printed jewelry models, creating marvelous customized rings with mesh or hollow shapes. The life of a product originates from its solution for users’ problems. From a machine to a product, MiiCraft brand story began to unfold.

Contact info

Tel:03-6206789#1039

Fax:03-6231111#1039

Email:nina.chen@youngoptics.com

Email:sales@miicraft.com