請用 Wechat 掃描台灣精品QRcode 或 搜尋ID: TaiwanExcellence

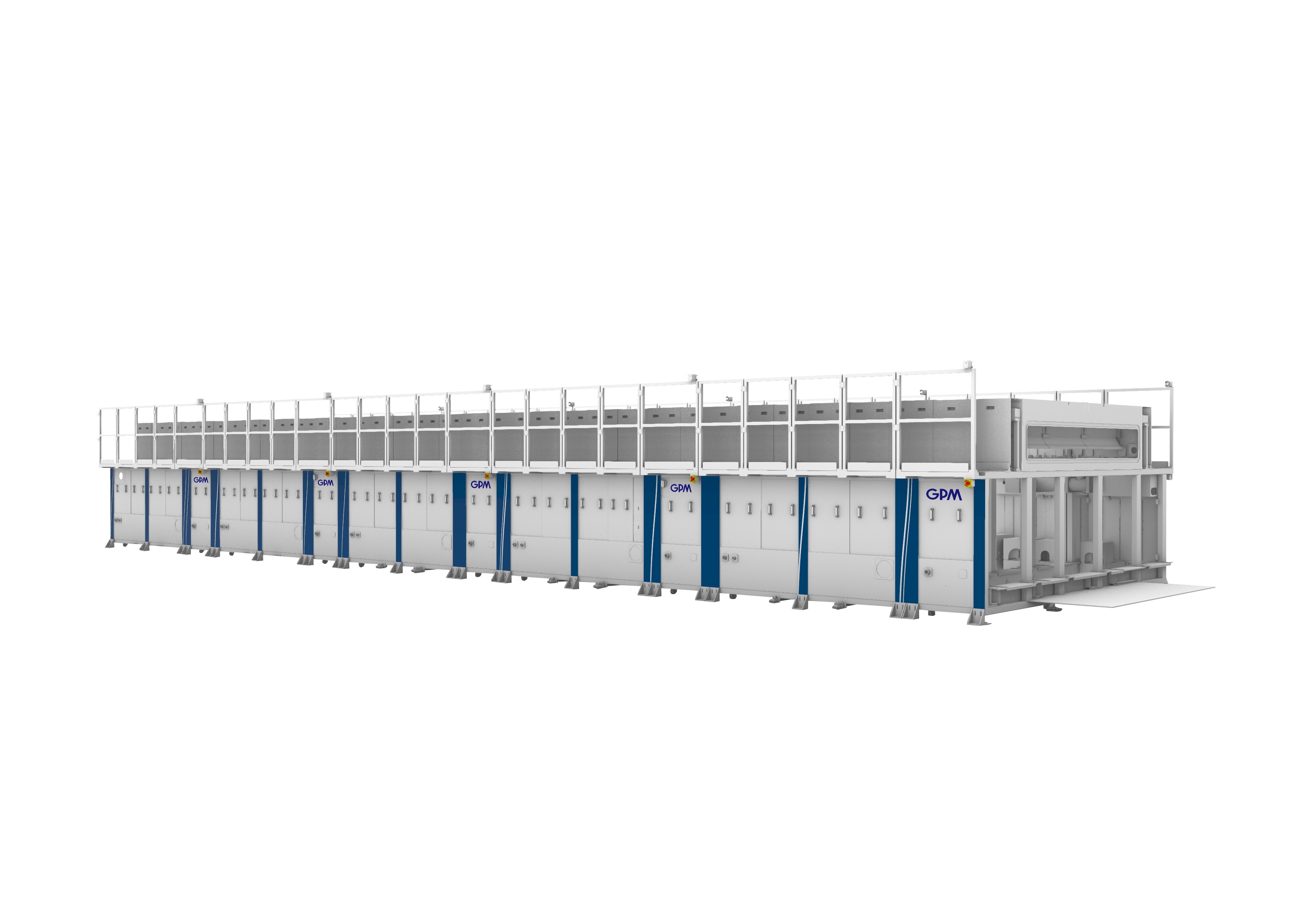

This product "Wet Etch machine" is wet etch equipment for next generation above G6. It is used in Cu, AL, ITO, IGZO process. The design of product is coupled with the chemical spray system, to satisfy the customer process capability.

This product has the characteristics of high equipment Up time, low substrate output Tact time, good etching Uniformity, low chemical and DI water consumption. It can provide energy saving and carbon reduction.

The Product Features and Innovative Technology

(1) Low substrate breakage rate:

1.Without double roller transfer system

2.Guide roller with side support

3.High collimation Dry AK

(2) High equipment up time:

1.Auto anti-crystal clean function

2.Auto chemical tank exchange function

3.Auto dual filter exchange function

4.Semi-auto chemical piping clean function

5.Equipment failure monitor system:IDMS

(3) Energy conservation:

1.Reduce chemical of substrate carry-out

2.Reduce DIW waste of substrate clean

3.Reduce chemical of exhaust by auto-damper

About Gallant Precision Machining Co.,Ltd.

Founded in 1978 and established the own brand “GPM”, Gallant Precision Machining (GPM) (TWSE: 5443) was listed on the Taiwan Stock Exchange in 1998. Starting out as a manufacturer of mold parts and components for semiconductor equipment, GPM gradually entered the process equipment, automation equipment, and precision mold part and component industries in 1985. Later in 2002 and 2006, GMP merged respectively with Kingbond and Kingroup Systems to enhance process technology RD, production, and manufacturing capabilities, thus allowing it to successfully enter the core supply chain of LCD, PV, PCB, biomedical, robot, and smart automation industries. Today, GPM products and services are distributed throughout Asia, with accounts across Greater China and Southeast Asia

In 1978, in a small apartment on Baoqiao Road in Xindian, under the leadership of Chairman upholding the concept of "people-oriented, excellence", GPM was born. Since the creation of the first IC mold, GPM has become the first semiconductor precision mold and equipment manufacturer of Taiwan's own brand "GPM" with firm belief and unparalleled courage. We, who constantly seek for new ideas and change, have completed the merger with "Hua-Dong Semiconductor Company" and "Kingroup Automation Company", bringing together the talents of the three companies. Developed its own corporate culture of "integrity, teamwork, innovation, learning, responsibility", and opened up a new world of domestic precision equipment. This year is the 42nd years since the establishment of GPM. We cherish the past and all the previous colleagues who have worked hard together. In the future, we will create a happy enterprise and take toward another brand-new "GPM".