請用 Wechat 掃描台灣精品QRcode 或 搜尋ID: TaiwanExcellence

The global wave of industrial automation and the demand for Industry 4.0 in various countries continue to rise. In response to the needs of industrial upgrade and factory optimization in various countries, Taiwan smart machinery industry combines its powerful ICT industry chain and precision machinery technology together providing overall smart production solutions which makes Taiwan the best choice during this global industrial upgrading phase. The outbreak of NCP (Novel coronavirus pneumonia) from China throughout the world has caused a global mask shortage. Taiwan machine tool industry has been assisting the mask manufacturing by arranging and setting up more production lines, taking an important role for international epidemic prevention.

In 2018, Taiwan machinery output a record high value at $1.18 trillion NT dollars with exports growing by 7.3%. Even with exports dropped by 8% due to the U.S.-China trade war in 2019, the total output value from overall machinery industry still maintained at $1.1 trillion NT dollars; also, orders have been picking up gradually with new orders under negotiation. The NCP outbreak has caused a 15.4% decrease in machinery exports in January comparing to last year; nevertheless, Taiwan machinery industry is all geared up for a glorious fightback. In addition to manufacturing industry returning to Taiwan for factory and production line expansions, many enterprises start deploying Southeast Asia, South Asia and other new southbound markets for factories and production lines. Governments from various countries continue promoting industrial automation and smartification will bring further and higher demands for smart machinery products. Mr. Ke, Ba-Xi, the chairman of the Taiwan Association of Machinery Industry, stated that due to industrial upgrading and the rigid demand from the machinery industry, Taiwan machinery equipment exports is looking at an increase of 5% to 10% this year.

As the tendency from production flexibility, detail customization and personalization grows higher, production solutions that can respond and coordinate in time are indispensable. The demand in mask production has expanded recently, Taiwan smart machinery has earned its place as a strong supportive industry in this regard. Despite the fact that NCP has caused a global shortage on mask, through the immediate response and mobilization from enterprises like Tongtai Machine & Tool Co., TPI Bearings, and Hiwin Technologies in supporting the establishment of a mask production line, the mask production lead-time went from its normal 45~60 days down to 25 days. The remarkable effort boosted the production to 10 million pieces from 3.2 million pieces a day filling an urgent market demand.

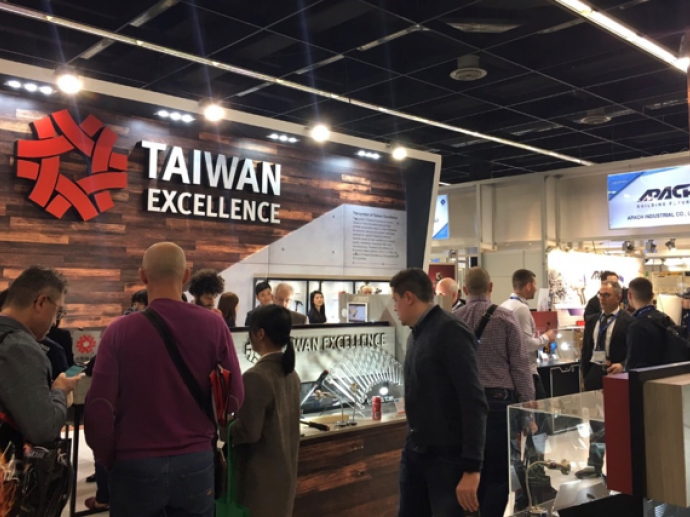

There are 46 enterprises in machinery industry have won the Taiwan Excellence Award, as the second highest proportion from all industries. It is obvious that Taiwan machinery product innovative capability and quality have been significantly recognized. Taiwan machinery industry have transformed from traditional production machines to manufacturing service solution providers, such as Equiptop HiTech Corp. with their “TD-ADC” smart precision grinder improving accuracy and precision by adopting digital control system cooperating with IIoT to tap into other facility equipment to create more precise and efficient production lines for customers. Automation equipment supplier, Buffalo Machinery launches “Axile ART” smart machinery monitoring system(2020 Taiwan Excellence Gold Award), which can quickly capture the production data, effectively assist managing the production line energy consumption and manufacturing processes through big data, resulting in great reduction of downtime rate. “Trackless moving robot” from GreenTrans Corp., offers extreme precise trackless guiding system to achieve unmanned operations with semiconductor production in clean room environment avoiding dust hazard during the production process. ACME Machinery's AM-ICD Dyeing Machinery utilizes smart controls to simplify dyeing process, not only it reduces the dyeing time and unifies textile color, it also significantly reduces the use of hydro consumption and CO2 emissions, solves the pollution issue from traditional dyeing by innovative process designs.

Machinery as the foundation of all industries. How to help clients in building more precise, efficient and flexible production lines is the ultimate goal of the smart machinery industry. As the leading country in mechanical production, Taiwan with high-precision machinery manufacturing technology, strong R&D backup and excellent response capabilities will be the strongest support for all countries in establishing high-efficiency factories.

CHUN-TSE, WU

Director of Strategic Marketing Department

Taiwan External Trade Department

Tel: +886 2-2725-5200 #1300

Email: wuct@taitra.org.tw

Previous article

2020-02-14

Next article

2020-02-14