請用 Wechat 掃描台灣精品QRcode 或 搜尋ID: TaiwanExcellence

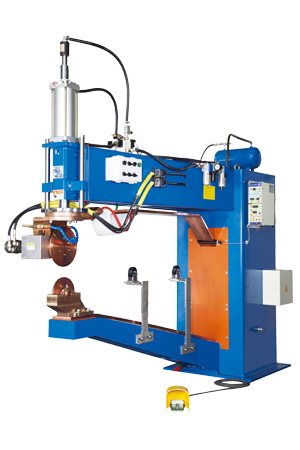

Generation Highly-Efficient Knife Shank Upsetter Machine used for top aseptic dining utensils & high-class cooking knives. It combines automation, customization & special features:

1.1 Quality:

Highly-efficient power saving function with excellent appearance quality forging, e.g. applied for making top aseptic dining utensils & high-class cooking knives.

1.2 Customized:

Customized design is for module electrode design; increases production capacity, competitiveness & productivity by 40%.

2. Human Factors Engineering:

2.1 Work-Efficient: no standby time, easy material loading, with automation & high level of production.

2.2 Visual Interface Design: digital work interface and ergonomics; lowers fatigue while raising production.

3. Expert Engineering & Function:

3.1 Save 34% power and is multi-functional.

3.2 Wiring design is dust-proof, reliable & in accordance with CE certification.

3.3 Can work with robots to achieve laborless production.

4. Green design: 75% iron & 20% copper in body; recyclable and meets EU RoHS.

About Da Jie Electricity Machinery Industrial Co., Ltd.

1. Company Vision: DA JIE, founded in 1973, selling products as its self-owned brand, has a vision of becoming the “global green, high-efficient and power-saving leading supplier of metal-heating applied equipment”. “DJE” uses strategy to “create the highest value to clients”, sets its core idea as “back pusher of the high quality chassis equalizing bar of automobiles”; products are applied in manufacture the chassis equalizing bar of automobiles for automobile industry.

2. Industry contribution: use intelligent control as core technology; offer clients power-saving welding passes with higher quality; elevate 100% of quality production rate & 54% in power-saving.

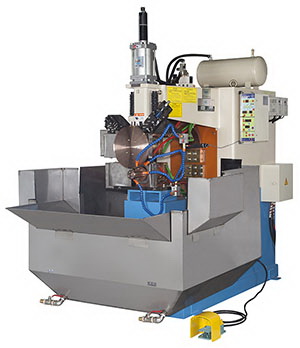

3. To fit the modern smart-production trend, we cooperate with clients to research and design intelligent production equipment “New Generation High-Efficient Power-Saving Inverter Heating Machine for Equalizing Bar of Automobiles” as a representative product.

1. Company Establishment and Brand History:

DJE founded in 1973 with the vision to “become Leader of global green and power-saving, high-efficient metal-heating applied equipment” and the strategy to “create highest value for clients”.

2. R&D History and millstone:

2000: Supply welding machine to five top vehicle companies.

2005: Products sold to Thailand, Malaysia, Indonesia, etc.

2007: Redesigned brand logo for globalization.

2009: Cooperate with OTC (Japan), robot-arm function combination; HONDA (Japan) qualified vendor.

2012: Vehicle springs fast-heating line with robot arms for S. Korean vehicles.

2013: OEM for NASTOA (Japan).

2014: Next-generation welder-controller system.

2015: Auto forging machines and wheel-welding machines; turnkey output and upgrading (integrated with controller system technology upgraded made in 2014).

2016: Water tank factory turnkey output to Asian market. Develop Innovative High-efficient 3 Phase Inverter Seam Welder for Water Tank.

Contact info

Tel:+886-4-2491-4588

Fax:+886-4-2491-4599

Email:dajieco@yahoo.com.tw

Tel:+886-4-2491-4588

Fax:+886-4-2491-4599

Email:dj07@dajieco.com

Tel:+886-4-2491-4588

Fax:+886-4-2491-4599

Email:dajieco@yahoo.com.tw

Tel:+886-4-2491-4588

Fax:+886-4-2491-4599

Email:dj06@dajieco.com

Tel:04-2491-4588

Email:ddajieco-marian@dajieco.com

Tel:04-24914588

Fax:04-24914599

Email:dajieco@yahoo.com.tw