請用 Wechat 掃描台灣精品QRcode 或 搜尋ID: TaiwanExcellence

1. Create Value with Innovative Technologies

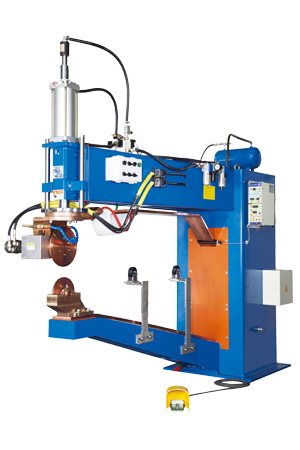

The welding current meets the certification of main vehicle manufacturers and ISO standard; Enable clients to elevate the welding quality and reduce power consumption. These welding machines own highly reliable reputation by local and oversea’s customers.

2. Elevate the CP Ratio over Efficient Modularized Design and Cost Control

Apply the efficient modularized design, in the prospective of fitting the various machine models and it can fast respond client’s tailor-made and quick-repair requirements.

2.1 Modularized parts and built-in special alarm function:

30 built-in memory conditions for the varied welding currents corresponding to different products, and easy to collect data for database. Low current at current compensation, low-temperature, SCR-trigger fault or control chip error will trig the alarm system. In case the fault causes machine shutdown, client can follow the error code to replace the fault parts quickly.

2.2 Easy for repair and production; with cost-deduction favor:Reduce 20% parts amount than the former generation’s products. The intelligent control system is designed into two control module boards, which can save repair cost.

3. Humanized op. Interface

3.1 Use LED display brand and button functions are fully compatible to the machine’s operating sequence; the buttons and colors are easy to understand.

3.2 Reduce welding hazard:

The full-cover acrylic door can avoid the error-touch and sustain the reliability of op. panel.

4. Green Product’s Design

4.1 Meet CE safety standard : anti-electric-shock for entire machine.

4.2 Over 95% parts can be recycled.

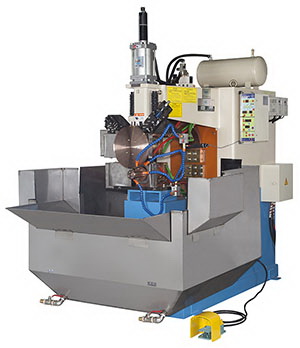

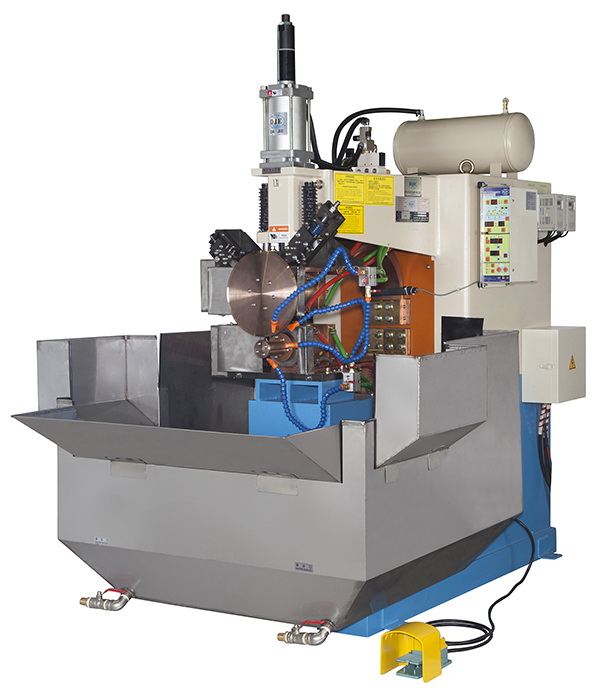

4.3 Varied-frequency-control transmission system: apply the VFC transmission system to replace the traditional oil pump; no oil pollution, low noise and power-saving.

4.4 The seam welding electrode is made of Cr-Mo alloy steel, which has thermo-resisting and low-wear character, and will extend lifetime for three times.

About Da Jie Electricity Machinery Industrial Co., Ltd.

1. Company Vision: DA JIE, founded in 1973, selling products as its self-owned brand, has a vision of becoming the “global green, high-efficient and power-saving leading supplier of metal-heating applied equipment”. “DJE” uses strategy to “create the highest value to clients”, sets its core idea as “back pusher of the high quality chassis equalizing bar of automobiles”; products are applied in manufacture the chassis equalizing bar of automobiles for automobile industry.

2. Industry contribution: use intelligent control as core technology; offer clients power-saving welding passes with higher quality; elevate 100% of quality production rate & 54% in power-saving.

3. To fit the modern smart-production trend, we cooperate with clients to research and design intelligent production equipment “New Generation High-Efficient Power-Saving Inverter Heating Machine for Equalizing Bar of Automobiles” as a representative product.

1. Company Establishment and Brand History:

DJE founded in 1973 with the vision to “become Leader of global green and power-saving, high-efficient metal-heating applied equipment” and the strategy to “create highest value for clients”.

2. R&D History and millstone:

2000: Supply welding machine to five top vehicle companies.

2005: Products sold to Thailand, Malaysia, Indonesia, etc.

2007: Redesigned brand logo for globalization.

2009: Cooperate with OTC (Japan), robot-arm function combination; HONDA (Japan) qualified vendor.

2012: Vehicle springs fast-heating line with robot arms for S. Korean vehicles.

2013: OEM for NASTOA (Japan).

2014: Next-generation welder-controller system.

2015: Auto forging machines and wheel-welding machines; turnkey output and upgrading (integrated with controller system technology upgraded made in 2014).

2016: Water tank factory turnkey output to Asian market. Develop Innovative High-efficient 3 Phase Inverter Seam Welder for Water Tank.

Contact info

Tel:+886-4-2491-4588

Fax:+886-4-2491-4599

Email:dajieco@yahoo.com.tw

Tel:+886-4-2491-4588

Fax:+886-4-2491-4599

Email:dj07@dajieco.com

Tel:+886-4-2491-4588

Fax:+886-4-2491-4599

Email:dajieco@yahoo.com.tw

Tel:+886-4-2491-4588

Fax:+886-4-2491-4599

Email:dj06@dajieco.com

Tel:04-2491-4588

Email:ddajieco-marian@dajieco.com

Tel:04-24914588

Fax:04-24914599

Email:dajieco@yahoo.com.tw