請用 Wechat 掃描台灣精品QRcode 或 搜尋ID: TaiwanExcellence

DJE’s vision aims to be global energy-saving and leader in metal heating machine and create value to customers.

1. Innovation: 3-phase saves power; weld current consumption saves 33%. (Current changes 250A /√3?144A), improves PF. from 0.4 to 0.7; Metal Industries Research & Development Center certified.

2. Modularity maintenance, achieves green production goal.

2.1 Intelligent control system enables to build database. Alarm signals if abnormal temperature, IGBT malfunctions, etc. User can solve problem by error code with NC controller.

2.2 Streamline design lower 30% use in components. 2 module panels are easy to maintain.

3. Humanized interface

3.1 Easy to operate in digitalized panel and man-machine interaction.

3.2 Interface’s sealed hard gel avoids error-touch; IP55 dust-proof, color-coded and protection guard ensure safety.

4. Green design

4.1 CE standard: Leakages prevent and electric-shock protection.

4.2 95% of parts are recyclable.

4.3 Safe English & Mandarin interface.

About Da Jie Electricity Machinery Industrial Co., Ltd.

1. Company Vision: DA JIE, founded in 1973, selling products as its self-owned brand, has a vision of becoming the “global green, high-efficient and power-saving leading supplier of metal-heating applied equipment”. “DJE” uses strategy to “create the highest value to clients”, sets its core idea as “back pusher of the high quality chassis equalizing bar of automobiles”; products are applied in manufacture the chassis equalizing bar of automobiles for automobile industry.

2. Industry contribution: use intelligent control as core technology; offer clients power-saving welding passes with higher quality; elevate 100% of quality production rate & 54% in power-saving.

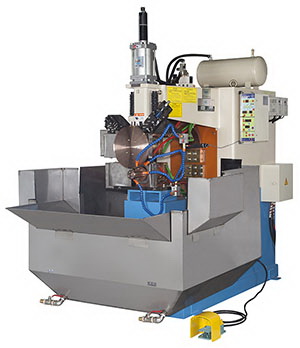

3. To fit the modern smart-production trend, we cooperate with clients to research and design intelligent production equipment “New Generation High-Efficient Power-Saving Inverter Heating Machine for Equalizing Bar of Automobiles” as a representative product.

1. Company Establishment and Brand History:

DJE founded in 1973 with the vision to “become Leader of global green and power-saving, high-efficient metal-heating applied equipment” and the strategy to “create highest value for clients”.

2. R&D History and millstone:

2000: Supply welding machine to five top vehicle companies.

2005: Products sold to Thailand, Malaysia, Indonesia, etc.

2007: Redesigned brand logo for globalization.

2009: Cooperate with OTC (Japan), robot-arm function combination; HONDA (Japan) qualified vendor.

2012: Vehicle springs fast-heating line with robot arms for S. Korean vehicles.

2013: OEM for NASTOA (Japan).

2014: Next-generation welder-controller system.

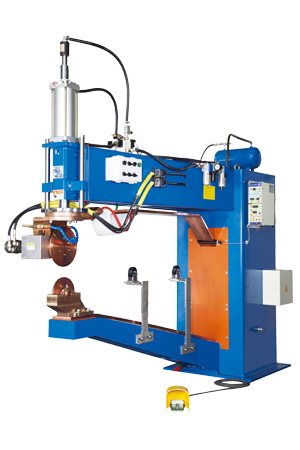

2015: Auto forging machines and wheel-welding machines; turnkey output and upgrading (integrated with controller system technology upgraded made in 2014).

2016: Water tank factory turnkey output to Asian market. Develop Innovative High-efficient 3 Phase Inverter Seam Welder for Water Tank.

Contact info

Tel:+886-4-2491-4588

Fax:+886-4-2491-4599

Email:dajieco@yahoo.com.tw

Tel:+886-4-2491-4588

Fax:+886-4-2491-4599

Email:dj07@dajieco.com

Tel:+886-4-2491-4588

Fax:+886-4-2491-4599

Email:dajieco@yahoo.com.tw

Tel:+886-4-2491-4588

Fax:+886-4-2491-4599

Email:dj06@dajieco.com

Tel:04-2491-4588

Email:ddajieco-marian@dajieco.com

Tel:04-24914588

Fax:04-24914599

Email:dajieco@yahoo.com.tw