請用 Wechat 掃描台灣精品QRcode 或 搜尋ID: TaiwanExcellence

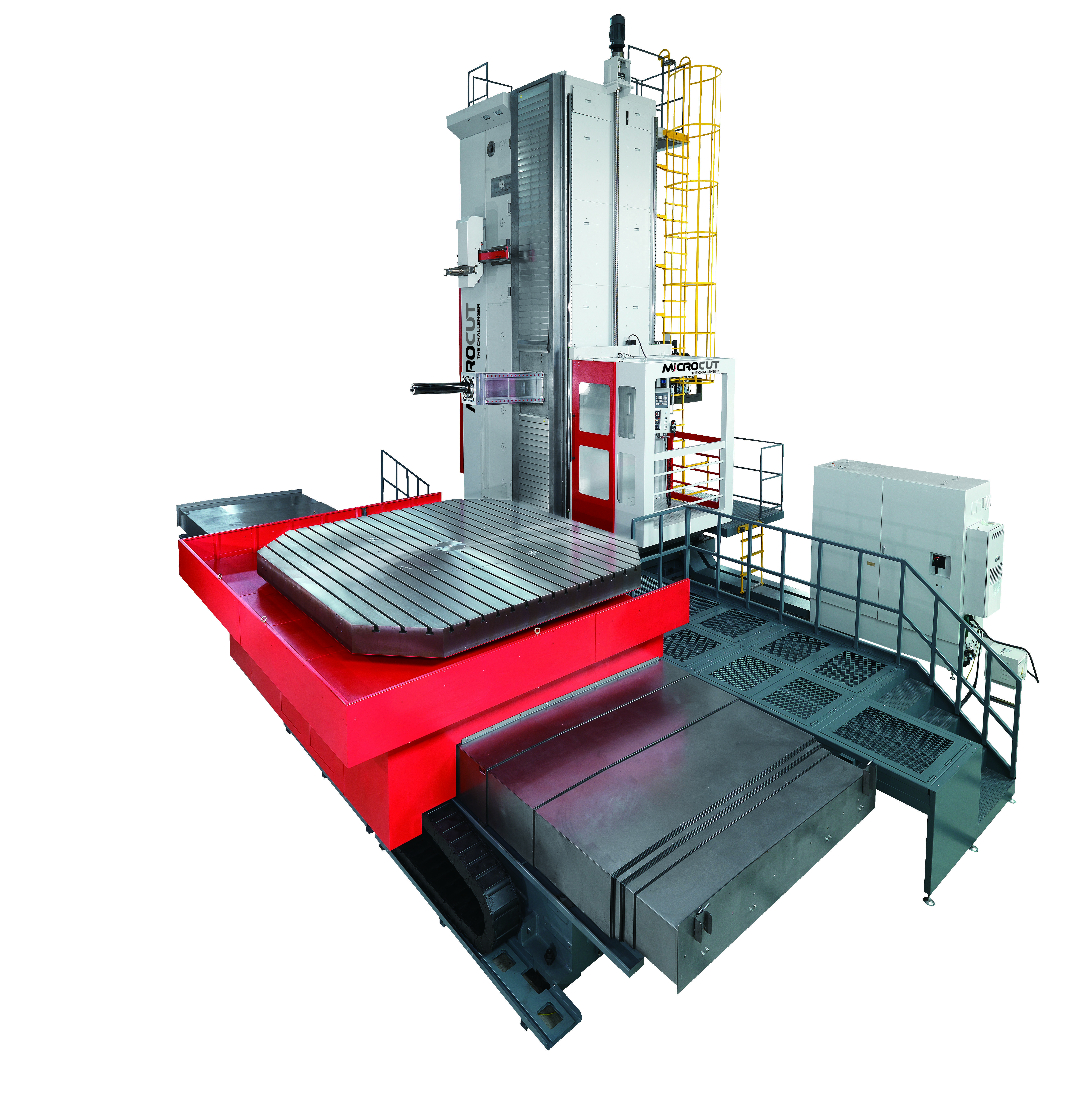

The Heavy Duty RAM-type Horizontal Boring Mills HBM-140RT is developed to satisfy the demands from oil, gas, shipbuilding, energy, and large mold industries. The ram-type spindle, through a series of simulation, analysis, implementation and dynamic modal tests, has features and capability that are in compliance with the ISO standards.

An automatic clamp/unclamp interface is set in front of the spindle to automatically change the accessory head in order to extend the scope of ram-type spindle, which is well-collocated to facing head, universal head and angle milling head and support fast conjunction to all appliances.

The smart Straightness Compensation Technology (SCT) is adopted to optimize the stability, which offsets the deformation caused by gravity when Ram or quill extends to retain the accuracy. The Spindle Vibration Supervision (SVS) is developed to avoid the RAM type spindle damage due to vibration. Both technologies have obtained the domestic and foreign patents.

Smart SCT is to ensure the machining accuracy for horizontal boring machine when the ram and quill are extended at full length. The SCT provides function to automatically compensate the deformation caused by the gravity which ensures the best linearity and machining accuracy within 3um.

SVS is the system to detect the operating status of the spindle together with send out effective warning, or automatically decrease the spindle speed to operate within safe ranges to further protect the spindle durability, the mechanism also ensures continuous operation of machinery and reduces serious loss owing to damage caused by spindle downtime.

The dual drive system table is to ensure the table backlash within 0.002um which can provide the turning function and to strengthen HBM-140RT functionality. Besides it can reduce the workpiece machining time and to improve competitiveness and ensure customer satisfaction.

About Buffalo Machinery Co., Ltd.

AXILE designs and builds agile smart 5-axis VMCs with leading automation solutions for manufacturers of complex parts and components. AXILE believes customers shouldn’t have to choose between high-speed and high-performance 5-axis machines. By combining sheer agility, digitalized intelligent automation, and a new standard of 5-axis machining, AXILE created an all-new approach: Agile Smart Machining.

AXILE’s dedicated team of industry experts brings together ultra-high removal rates, pinpoint precision, and 24/7 production reliability within each and every AXILE 5-axis machine. The breakthrough design concepts and advanced proprietary technologies serve highly sophisticated manufacturers of complex parts and components for applications in aerospace, die and mold, medical, and semiconductor, among others.

The AXILE service and support network spans nearly 50 countries, with more than 80 distributors across Asia, Europe, and the Amercias. We have service centers in Europe and USA.

Agile Smart Machining is a promise from AXILE to manufacturers to make industry 4.0 a reality. We developed this all-new approach to bring manufacturers significantly shorter processing times, flexible and optimized production, zero unscheduled downtime, and most importantly a way to operate without wasting resources.

We are introducing the future of full 5-axis machining, made available today. Finding that perfect balance of speed and precision allows manufacturers to respond effectively to new opportunities and demands in the market. For manufacturers seeking agile machining solutions, AXILE delivers ultra-high removal rates and pinpoint precision for complex parts and components of a variety of sizes and materials.

Digitalized Intelligent Automation is AXILE’s brand of smart manufacturing, combining advanced machining technologies, reliable automation solutions, and insight from data to ensure optimal operations without much human intervention.

Contact info

Tel:04-25603759#108

Fax:04-25603769

Email:a15@mail.buffalo.com.tw

Tel:04-25603759#120

Fax:04-25603769

Email:a15@mail.buffalo.com.tw