請用 Wechat 掃描台灣精品QRcode 或 搜尋ID: TaiwanExcellence

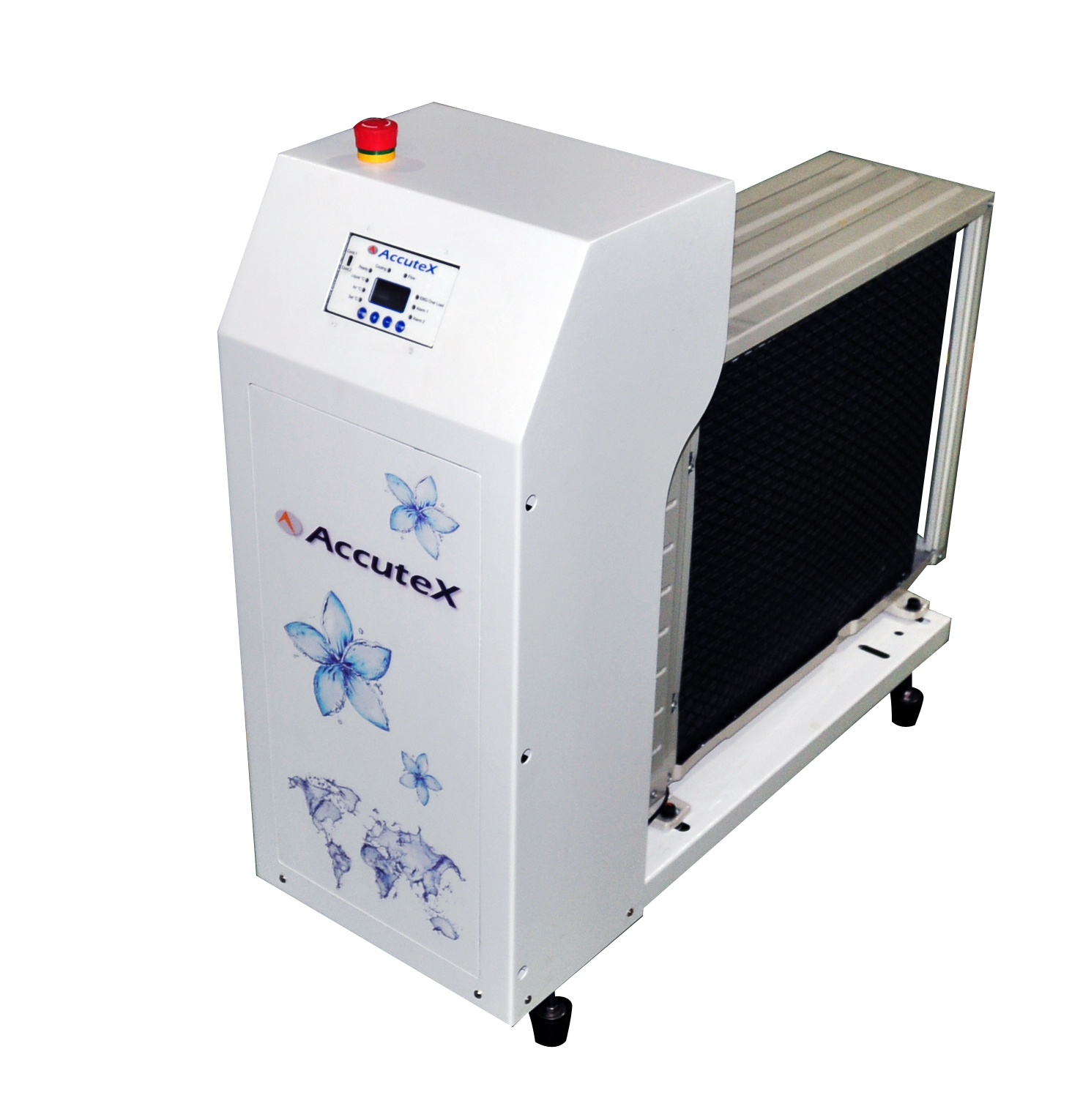

Accutex chiller is a cooling system for working fluid of machine tool capable of being assembled to various machine tools. Such cooling system for working fluid includes a cooling host and a heat exchanger, in which the cooling host is a commercial available cooling host and can be individually replaced by another, thus the cooling host can be assembled and repaired easily. By connecting with the heat exchanger, is quite different from the conventional, which applies a vaporizer to connect with the cooling system to cool down the working fluid in the system with gas states.

A.Down: lower electricity costs, savings of 15,000 one year:

AccuteX designated commercial conditioner brand , cooling efficiency

in line with national standards.

General industrial chiller no national standards for certification, each

respective experiment declared freezing capacity.

B.Excellent cooling efficiency UP 35%:

C.Stable cooling output:

AccuteX designated exchanger heat brand

1. The material is stainless steel(SUS316L), long life and corrosion

resistance.

2. Small, reduce external heat source interference.

3. High heat exchange efficiency and stability.

Other exchanger heat brand

Exchange efficiency is low and unstable heat , cooling water

temperature instability and affect machining accuracy.

D.Easy Maintenance:

Mean Time To Recovery

Accutex0.5-1 day:More than 95% of standard parts can be

purchased in air-conditioning and hardware store.

Others3-5 days:It takes time to wait for parts and technical support

only from manufacturer.

About Accutex Technologies Co., Ltd

“Accutex Technologies”, the title of which consists of high-accuracy technology, is founded on the technology of Mechanical and System Research Laboratories team of ITRI who were the original controller designer and supplying controllers to several Taiwan WEDM companies and has contributed to the WEDM field over 29 years.

The core of Accutex technical team was composed by ITRI people who has become a paragon in knowledge economy of Taiwan machinery as well as mastering 100% key technologies, like CNC controller, power discharging, machine / IC designing, which makes Taiwan become worldwide number 3 in WEDM production independently after Japan and Switzerland.

We also establish different strategic partners, such as AccuteX KOREA, AccuteX USA, AccuteX CHINA, 100% OBM products and therefore have the global brand value. The users’ needs are always our top priority consideration, to direct product development from design to service.

In 1990s, Taiwan EDM occupied 60% market in the world. EDM with low technologies and slight profit, the industry shall be restructured urgently. At the same time, Wire EDM (WEDM) just sprouted and many demands in the market, however, EDM manufacturers didn’t have any resource because all the market was occupied by the Switzerland and Japan. In the case of foreign suppliers were reluctant to provide critical CNC controller, discharge power and technical support, ITRI from nothing to open the WEDM project and self-developed PC Based, CNC Controller, discharge power also successfully transferred technologies to domestic EDM manufacturers, in short 10 years, Taiwan become worldwide no. 3 in WEDM market after Switzerland and Japan. “Accutex Technologies”, composed by originator of ITRI team from 2001, under the project of Ministry of Economic Affairs, we are still keep going to make lot of effort in accuracy technologies for Taiwan WEDM Industry.

Contact info

Tel:04-23599688#227

Fax:04-23596967

Email:josephine.shaw@accutex.com.tw

Tel:04-23599688#229

Fax:04-23596967

Email:zoesu@accutex.com.tw

Tel:04-23599688#239

Fax:04-23596967

Email:davidwebb@accutex.com.tw

Tel:04-23599688#229

Fax:04-23596967

Email:zoesu@accutex.com.tw