請用 Wechat 掃描台灣精品QRcode 或 搜尋ID: TaiwanExcellence

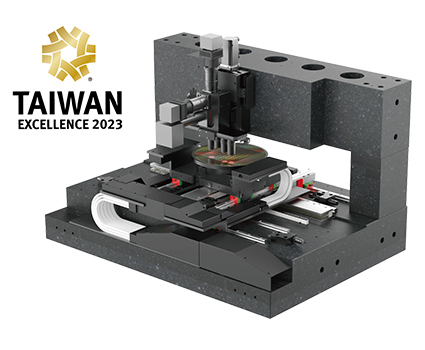

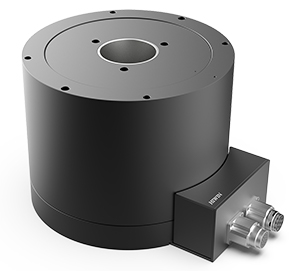

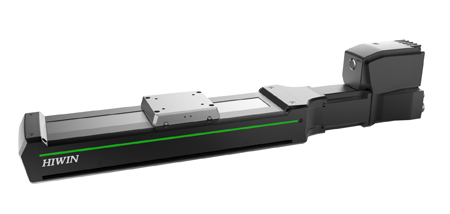

DiAMOND- new generation positioning stage with nano accuracy, applicable in semiconductor and FPD industries. It is realized by technologies like vacuum preloaded air bearing and friction elimination, which enable nano accuracy in a thousandth second and increases equipment reliability.

Main features:

Dynamic-balance:

It performs extraordinary nano motions with unique counter balancing and mass compensation algorithm.

Astro-precision:

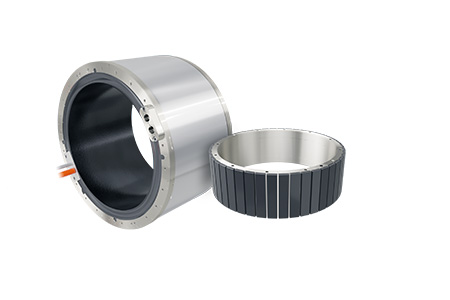

Linear motor, porous air bearing and precision SiC ceramic guide are used and stable servo drive ensures long term reliability and accuracy.

Modularization & Organic:

With highly modularized green design and manufacturing, it meets Class 10 clean room regulation and satisfies low particle emission need.

Novel-Design:

Patents in the technology of counter balance and mass compensation in main industrial countries are applied.

The novel design of DiAMOND combines the imagery of Chinese martial art- Tai Chi. The base structure provides stability, while the reaction force counter balancing technology deals with vibration, thus nano level accuracy can be achieved. As the masterpiece of precise positioning stage, it demonstrates a perfect balance of strength and gentleness.

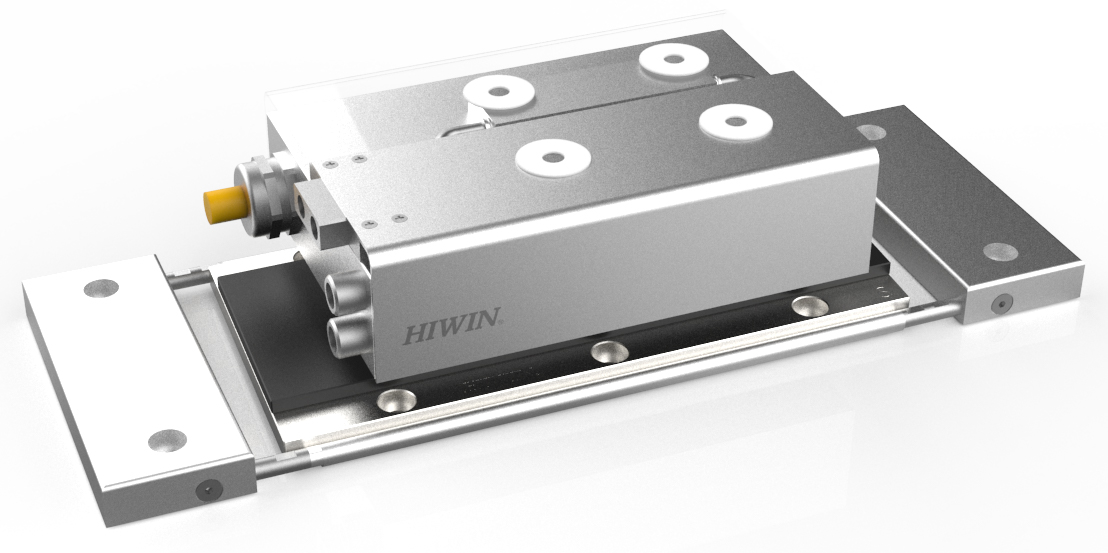

HIWIN commits continuously efforts to providing vertical integrated solutions to the industry. It shortens development time and saves costs for customers with remote detection capability and global supports. This enables users to focus on their know-hows, such as inspection, image processing or laser machining.

Its core parts are: linear motor, servo drive, air bearing, parallel spring etc. They are designed by own R&D team and assembled in factory of Da-Du mountain in Taichung by experienced technicians. System software are done by own programming team. With such teams, an early beta-site validation becomes always possible.

It is EtherCAT conformance tested, Function Safety and CE certified. HIWIN received in 2002 ISO14001 and in 2011 OHSAS18001 TOSHMS certifications.

About HIWIN MIKROSYSTEM CORP.

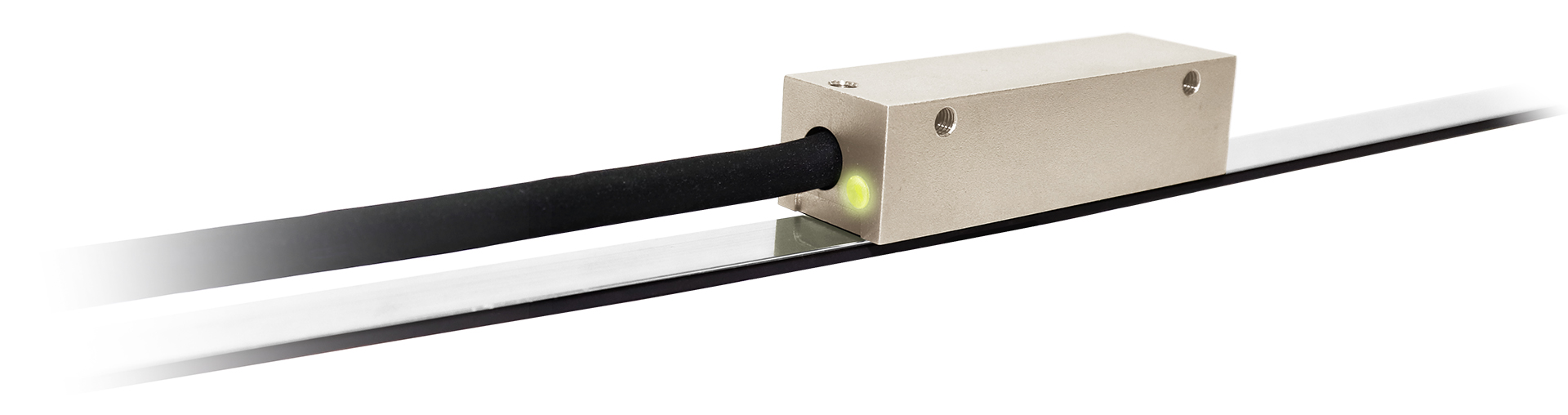

HIWIN MIKROSYSTEM Corp. has been dedicated to the development and manufacturing of components, systems for linear motion and positioning control. With a complete product line, we provide different types of nano-positioning stages, torque motors, linear motors, direct drive motors, spindle motors, servo motors, vacuum motor, drive, controller, linear actuators and position measurement systems . Our product applications span various precision industries, such as semiconductor, automation, machine tool, biotech and construction. Headquartered in Taiwan, HIWIN MIKROSYSTEM Corp. has established subsidiary in Germany,Japan,USA,Italy,Switzerland,Czech Republic,Frace,Bulgaria,etc. HIWIN MIKROSYSTEM was certificated ISO9001,ISO14001,ISO14064-1,ISO45001,ISO50001 and wins several national awards. Our philosophy of management is to integrate global resources for continuous innovation and to provide high value-added products to customers through the practice of innovation, quality and service.

HIWIN MIKROSYSTEM is the driving force for the "direct drive precision technology". Since its founding in 1997, it has constantly accumulated experiences and become the first "advanced direct drive technology" leading brand in Taiwan. "HIWIN MIKROSYSTEM" is constantly improving its independent R&D technology and capability. With the headquarters in Taiwan as the center, we have set up R&D centers both at home and abroad, with more than 200 researchers engaging in the R&D of new products and "key processes". We have accumulated many years of excellent experiences, have more than 642 patents, met the requirements of precision technology, you understand our job by imagining the achievement of the “precision positioning technology that enables one to see an ant in Manhattan, New York from the outer space”, and been committed to becoming the best partner to assist global precision equipment customers to achieve success.

Contact info

Tel:04-23550110#9245

Fax:04-23550123

Email:calvin@hiwinmikro.tw

Tel:04-23550110#9245

Fax:04-23550123

Email:rickylee@hiwinmikro.tw

Tel:04-23550110#9160

Fax:04-23550123

Email:lin650331@hiwinmikro.tw